PURPOSE OF COMPRESSOR

The compressor section of the gas

turbine engine has many functions. Its primary function is to supply air in

sufficient quantity to satisfy the requirements of the combustion burners.

Specifically, to fulfill its purpose, the compressor must increase the pressure

of the mass of air received from the air inlet duct, and then, discharge it to

the burners in the quantity and at the pressures required.

A secondary function

of the compressor is to supply bleed-air for various purposes in the engine and

aircraft. The bleed-air is taken from any of the various pressure stages of the

compressor.

The exact location of the

bleed ports is dependent on the pressure or temperature required for a

particular job. The ports are small openings in the compressor case adjacent to

the particular stage from which the air is to be bled

Air is often bled from the final or highest

pressure stage since, at this point, pressure and air temperature are at a

maximum.

Some of the current applications of bleed air

are:

1.

Cabin

pressurization, heating, and cooling;

2.

Deicing

and anti-icing equipment;

3.

Pneumatic

starting of engines; and

4.

Auxiliary

drive units (ADU).

The two principal

types of compressors currently being used in gas turbine aircraft engines are

1.

CENTRIFUGAL FLOW

COMPRESSOR

2.

AXIAL FLOW COMPRESSOR

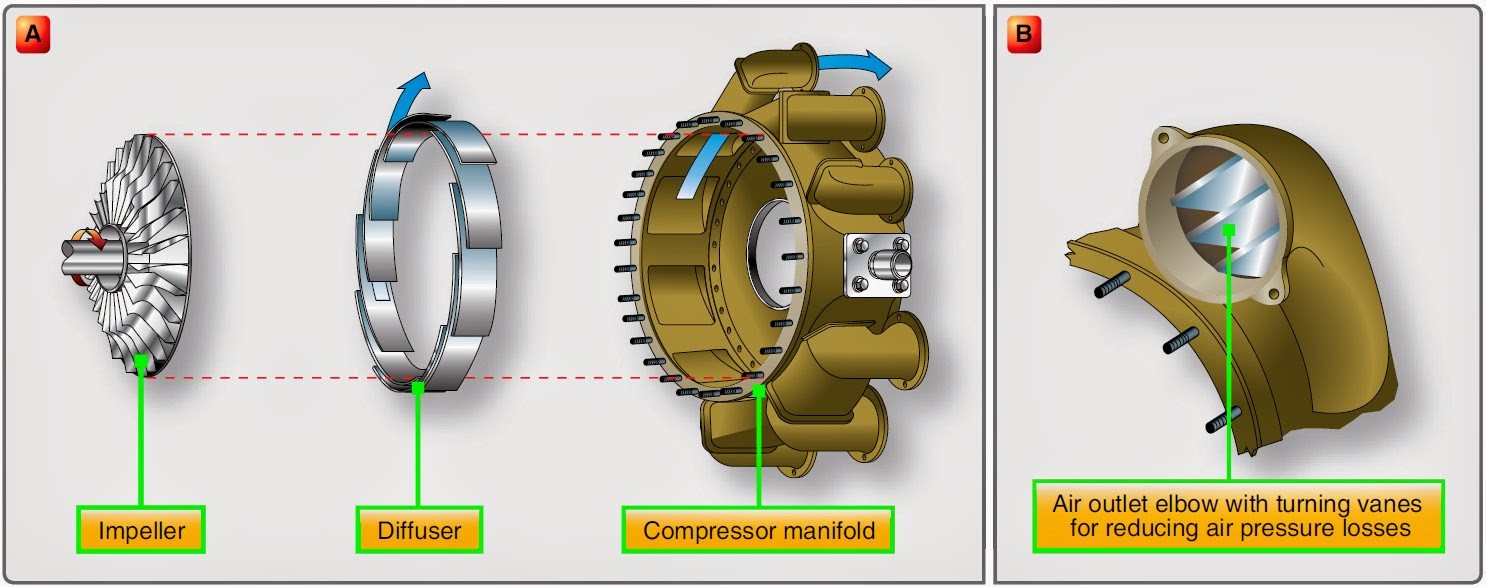

CENTRIFUGAL COMPRESSOR

CONSTRUCTIONAL FEATURES

The centrifugal-flow compressor consists

of an impeller, a diffuser, and a compressor manifold. Generally centrifugal compressors are limited

to two stages due to efficiency concerns.

The two main functional elements are the

impeller and the diffuser. Although the diffuser is a separate unit and is

placed inside and bolted to the manifold, the entire assembly (diffuser and

manifold) is often referred to as the diffuser. The impeller is usually made

from forged aluminum alloy, heat treated, machined, and smoothed for minimum

flow restriction and turbulence.

The above two figures shows

the basic construction of a centrifugal compressor

Principle of Operation

Air is sucked into the

impeller eye through an accelerating nozzle and whirled round at high speed by

vanes of impeller disc.

Due

to rotation of impeller at high speed the kinetic energy and pressure of

incoming air will increase and directed towards the diffuser. In diffuser the

pressure will increase further required for combustion.

Function of Impellers

Impeller consist of forged disc with

integral blades fastened by a splined coupling to a common power shaft

The function of the impeller is to take

the air in and accelerate it outward by centrifugal force

Impellers may be either of two types -- single entry

or double entry. The principal differences between the two types of impellers

are size and ducting arrangement.

·

The double-entry

type has a smaller diameter but is usually operated at a higher rotational

speed to ensure enough airflow.

·

The single-entry

impeller must be large in diameter to deliver the same quantity of air as the

double-entry type. This of course, increases the overall diameter of the engine

Function

of diffuser

·

The diffuser is

an annular chamber provide with a number of vanes forming a series of divergent

passages into the manifold.

·

The function is to transform high kinetic

energy of fluid at impeller outlet into high static pressure satisfactory for

combustion chambers. .

·

The diffuser vanes direct the flow of air from

the impeller to the manifold at an angle designed to retain the maximum amount

of energy imparted by the impeller.

Types

1.

Single stage centrifugal compressor

Single

stage compressor has only one stage of compressor mounted on main shaft.

In a

single stage we can obtain the required pressure and velocity for combustion

and its size will vary according to required pressure

2.

Multi stage centrifugal compressor

Multistage centrifugal compressors

consist of two or more single compressors mounted in tandem on the same shaft.

The air compressed in the

first stage passes to the second stage at its point of entry near the hub. This

stage will further compress the air and pass it to the next stage if there is

one.

The problem with this type

of compression is in turning the air as it is passed from one stage to the

next.

3.

Double entry centrifugal compressor

Double sided or double entry

compressors have two impellers mounted back to back

The air

compressed in one side is directed to other side for another compression and

from the other side the compressed air is directed towards combustion chamber

The process of directing

air from one side to other side is difficult

ADVENTAGES

- High

pressure rise per stage.

- Efficiency

over wide rotational speed range.

- Simplicity

of manufacture with resulting low cost.

- Low

weight.

- Low

starting power requirements.

DISADVENTAGES

- Its large frontal area for a given airflow

- Losses in turns between stages.

AXIAL FLOW COMPRESSOR

Axial flow

compressors produce a continuous flow of compressed gas, and have the benefits

of high efficiency and large mass flow rate, particularly in relation to their size

and cross-section. However, require several rows of airfoils to achieve a large

pressure rise, making them complex and expensive relative to other designs

A pair of

rotating and stationary airfoils is called a stage. The rotating airfoils, also

known as blades or rotors, accelerate the fluid. The stationary airfoils, also

known as stators or vanes, convert the increased rotational kinetic energy into

static pressure through diffusion and redirect the flow direction of the fluid,

preparing it for the rotor blades of the next stage. The cross-sectional area

between rotor drum and casing is reduced in the flow direction to maintain an

optimum Mach number using variable geometry as the fluid is compressed.

CONSTRUCTION

The rotor

features either drum-type or disk-type construction. The drum-type rotor

consists of rings that are flanged to fit one against the other, wherein the

entire assembly can then be held together by through bolts. This type of

construction is satisfactory for low-speed compressors where centrifugal

stresses are low

. The disk-type rotor consists of

a series of disks machined from aluminum forgings, shrunk over a steel shaft,

with rotor blades dovetailed into the disk rims. Another method of rotor

construction is to machine the disks and shaft from a single aluminum forging,

and then to bolt steel stub shafts on the front and rear of the assembly to

provide bearing support surfaces and splines for joining the turbine shaft.

The rotor blades are usually

made of stainless steel with the latter stages being made of titanium. The

design of blade attachment to the rotor disk rims varies, but they are commonly

fitted into disks by either bulb-type or fir-tree methods.

DRUM TYPE

The blades are then locked into place by differing methods. Compressor blade tips are reduced in thickness by cutouts, referred to as blade profiles.

DISC TYPE

These profiles prevent serious

damage to the blade or housing should the blades contact the compressor

housing.

.

PRINCIPLE OF OPERATION

The basic principle of operation of axial flow compressor is same as

that of centrifugal compressor but the compression takes place in axial

direction. In

this compressor, rotor impart kinetic energy to the air and this kinetic energy

is converted to pressure rise using stator through diffusion. It also redirects

the fluid at an angle suitable for entry into the rotor of following

stages

FUNCTION OF ROTOR

The rotor blades increase the air velocity. When air velocity

increases, the ram pressure of air passing through a rotor stage also

increases. This increase in velocity and pressure is somewhat but not entirely

nullified by diffusion. When air is forced past the thick sections of the rotor

blades static pressure also increases. The larger area at the rear of the

blades (due to its airfoil shape) acts as a diffuser.

FUNCTION OF STATOR

The stator vane row behind this rotor is configured as

a diffuser to slow the airflow down again by turning it back parallel to the

rotor axis. In so doing, it converts that excess velocity into a rise in static

pressure. Modern engines can achieve a pressure rise of up to 40-50% (absolute

pressure) per stage.

They also control the

direction of air to each rotor stage to obtain the maximum possible compressor

blade efficiency.

FUNCTION OF INLET

GUIDE VANE

The guide vanes direct the airflow into the first

stage rotor blades at the proper angle and impart a swirling motion to the air

entering the compressor. This preswirl, in the direction of engine rotation,

improves the aerodynamic characteristics of the compressor by reducing drag on

the first stage rotor blades. The inlet guide vanes are curved steel vanes

usually welded to steel inner and outer shrouds.

ADVENTAGES

- High peak efficiencies;

- Small frontal area for given

airflow;

- Straight-through flow, allowing

high ram efficiency; and

- Increased pressure rise by

increasing number of stages, with negligible losses.

DISADVENTAGES

- Good efficiencies over only

narrow rotational speed range,

- Difficulty of manufacture and

high cost,

- Relatively high weight, and

- High starting power requirements

(partially overcome by split compressors).

Compressor Stall and Surge

Surge will takes place when maximum discharge pressure is obtained at minimum flow and

vice versa for a particular speed. Now surge is the operating point, where Maximum head and minimum flow capacity is

reached.

Now principle of working of

a compressor is - Imparting Kinetic Energy to the fluid in impeller and

conversion of this energy into pressure energy by decreasing speed in Diffuser.

So, if maximum head capacity is reached, then pressure in diffuser will be

greater than pressure at impeller outlet.

This will prevent fluid from moving further at

impeller outlet and causes the fluid in diffuser to flow back, i.e. flow

reversal takes place. This can be deteriorating as it has potential to

damage rotor bearings, rotor seals, compressor driver and affect the whole

cycle operation, and also cause high vibrations and high temperature,.

This can be rectified by providing an anti surge valve, which takes

fluid from discharge and directs it to suction so that flow is increased and

surge is controlled.

A compressor can be brought out of surge in a number

of ways. The most obvious is to increase flow (Antisurge Valves). Decreasing discharge

pressure and/or increasing speed are other ways to move out of a surge

condition.

Compressor

manufacturers usually perform an aerodynamic performance test before delivering

the compressor. Determination of the compressor’s actual surge limit is a very

important aspect of the manufacturer’s shop testing program.

In

above graph, the line joining minimum flow points for each speed is called

Surge Line, and compressor must operate to the right side of it.

Compressor Stall

A compressor stall is a local disruption of the airflow in a gas

turbine or turbocharger compressor. It is related to compressor surge

which is a complete disruption of the flow through the compressor.

There are two types of

compressor stall:

Rotating stall

Rotating stall is a local disruption of airflow within the

compressor which continues to provide compressed air but with reduced

effectiveness. Rotating stall arises when a small proportion of airfoils

experience airfoil stall disrupting the local airflow without destabilizing the

compressor. The stalled airfoils create pockets of relatively stagnant air

(referred to as stall cells) which, rather than moving in the flow

direction, rotate around the circumference of the compressor. The stall cells

rotate with the rotor blades but at 50–70% of their speed, affecting subsequent

airfoils around the rotor as each encounters the stall cell

Axi-symmetric stall

or compressor surge

Axi-symmetric stall, more commonly known as compressor surge; or pressure

surge, is a complete breakdown in compression resulting in a

reversal of flow and the violent expulsion of previously compressed air out

through the engine intake, due to the compressor's inability to continue

working against the already-compressed air behind it. The compressor either

experiences conditions which exceed the limit of its pressure rise capabilities

or is highly loaded such that it does not have the capacity to absorb a

momentary disturbance, creating a rotational stall which can propagate in less

than a second to include the entire compressor.

FACTOR

WHICH CAUSE SURGE/STALL

·

Ingestion of foreign objects which

results in damage, as well as sand and dirt erosion, can lower the surge line.

·

Dirt build-up in the compressor and wear

that increases compressor tip clearances or seal leakages all tend to raise the

operating line.

·

Aircraft operation outside its design

envelope

·

Engine operation outside its flight

manual procedures.

·

Turbulent or hot airflow into the engine

intake, e.g. use of reverse thrust at low forward speed, resulting in

re-ingestion of hot turbulent air or, for military aircraft, ingestion of hot

exhaust gases from missile firing.

RESPONSE AND RECOVERY

The appropriate response to compressor

stalls varies according to the engine type and situation, but usually consists

of immediately and steadily decreasing thrust on the affected engine. While

modern engines with advanced control units can avoid many causes of stall, jet

aircraft pilots must continue to take this into account when dropping airspeed

or increasing throttle.