· Air intakes form the first component of all air breathing propulsion systems.

· The word Intake is normally used in the UK and Inlet in the United States.

· Air intakes are usually manufactured by the airframe manufacturer in coordination with the engine manufacturer.

· An aircraft may have one or more intakes depending upon the engine

· Air intakes are required to capture freestream air, sometimes change its direction and then supply this to the engine.

· This must be with as little flow distortion (non-uniformity) as possible.

PURPOSE OF INLET DUCT

· The purpose of the engine inlet duct is to provide the engine compressor with a uniform supply of air in order to prevent the compressor from stalling.

· Since the inlet is directly exposed to the impacting airflow, it must also create as little drag as possible.

· It has been found that even the smallest discontinuity of airflow supply can cause major engine problems as well as significant efficiency losses.

· The inlet duct is to retain its function of providing sufficient air with a minimum of turbulence, it should be kept clean and close to a condition as if it was new.

· Intake must ensure proper operation over the entire flight regime.

Modern aircraft intakes also contain noise-absorbing materialsBifurcated intakes or Y shaped intakes

Serpentine intakes for next generation military aircraft

FUNCTION OF INLET DUCT

· The inlet duct, found on most business and commercial jet aircraft, is of fixed geometry and is divergent of shape.

· Divergent means that its diameter increases from front to back. As air enters the aerodynamically contoured shape it starts to diffuse, arriving at the compressor at a slightly higher than ambient pressure.

· The reason why static pressure increases is because volume increases as well, thus velocity should decrease according to Bernoulli theorem.

· In general, the inlet ducts' shape allows the air to diffuse in the front portion of the inlet and to progress at a fairly constant pressure to the compressor section. This causes a much smoother supply of air at a more constant pressure and consequently better engine performance.

·

As speed increases inlet pressure

increases as well, adding significantly to the mass airflow until the aircraft

reaches its cruising speed. At this point the compressor reached its

aerodynamic design point and produces its optimum compression ratio together

with best fuel efficiency.

TYPES OF INLET

1. SUBSONIC INLET

2. SUPERSONIC INLET

SUBSONIC INLET

· Subsonic intakes consist of surfaces with smooth continuous curves.

· Usually such intakes have a thick leading edge: lip.

· Intakes of turboprops are slightly more complicated due to the presence of the propeller and the gearbox.

· Most subsonic intakes have fixed geometries.

· Some of the high bypass ratio turbofans have blow-in-doors. These are designed to deliver additional air to the engine during take-off and climb.

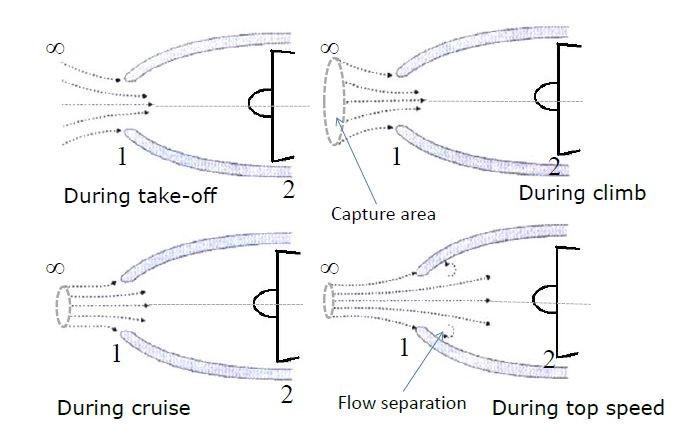

· Intake operation varies tremendously over the operating range of the engine.

· During take-off the engine requires high mass flow, but is operating at a lower speed.

· A typical fixed geometry intake may have problems delivering this mass flow.

· The intake design must ensure that under these extreme operating conditions too the intake performance is not drastically affected.

SUPERSONIC INLET:

· Supersonic intakes are usually more complicated than subsonic intakes.

· Design of supersonic intakes often involve trade-offs between efficiency, complexity, weight and cost.

· Supersonic intakes consists to two segments: a supersonic diffuser where the flow is decelerated from supersonic to subsonic through a series of shocks; this is followed by a subsonic diffuser where the flow is decelerated from high subsonic to lower subsonic speeds.

· Supersonic intakes may be classified in the following ways:

1. Axisymmetric or two-dimensional

· Axisymmetric: central cone for shock fixture

· Two-dimensional: rectangular cross-section

2. Variable or fixed geometry

· Variable: the central cone may be movable or in a rectangular intake, one of the walls may be adjustable

· Fixed: Geometry is fixed

3.Internal, external or mixed compression

· Depending upon the location of the shocks

· Internal compression intakes have shocks that are located within the intake geometry

· External compression intakes have shocks located outside the intake

· Mixed compression intakes have shock that are located within as well as outside the intake geometry